Hot Runners

Rheo-Pro® hot runner systems, controllers and manufacturing solutions guarantee part-to-part consistency, reduced mold maintenance, and increased production uptime and profitability.

iVG™

Clean, Compact and Durable

The new Rheo-Pro® iVG™ is the world's first and only internal valve gate nozzle. It is the only pneumatic valve gate hot runner that operates entirely without elastomeric seals, lubricants, or cylinder cooling. Unlike electric actuators, the iVG™ can operate at extreme temperatures of up to 400°C (750°F). Its patented design completely rewrites the rules of valve gating technology and creates endless new possibilities, from high cavitation to single drop hot runner systems.

Black Box™

Valve Gate Actuators without Cooling

New Rheo-Pro® Black Box™ pneumatic valve gate cylinders performs even under the most extreme operating conditions by doing away with elastomeric seals, lubricants, and cooling. The new technology is ideal for any molding environment, including high temperature and clean room applications. Black Box actuators reduce hot runner maintenance and extend the life of your mold.

M3 Series

The Future of Micro

M3 series micro molding machines offer unparalleled performance in an extremely compact, user-friendly package. The M3 platform features patented ISOKOR™ injection technology, specifically developed to address the unique challenges of molding very small, direct gated plastic parts. From low volume prototyping to fully automated mass production, the revolutionary M3 delivers superior part quality, faster speeds, and more flexibility.

High Performance

Systems

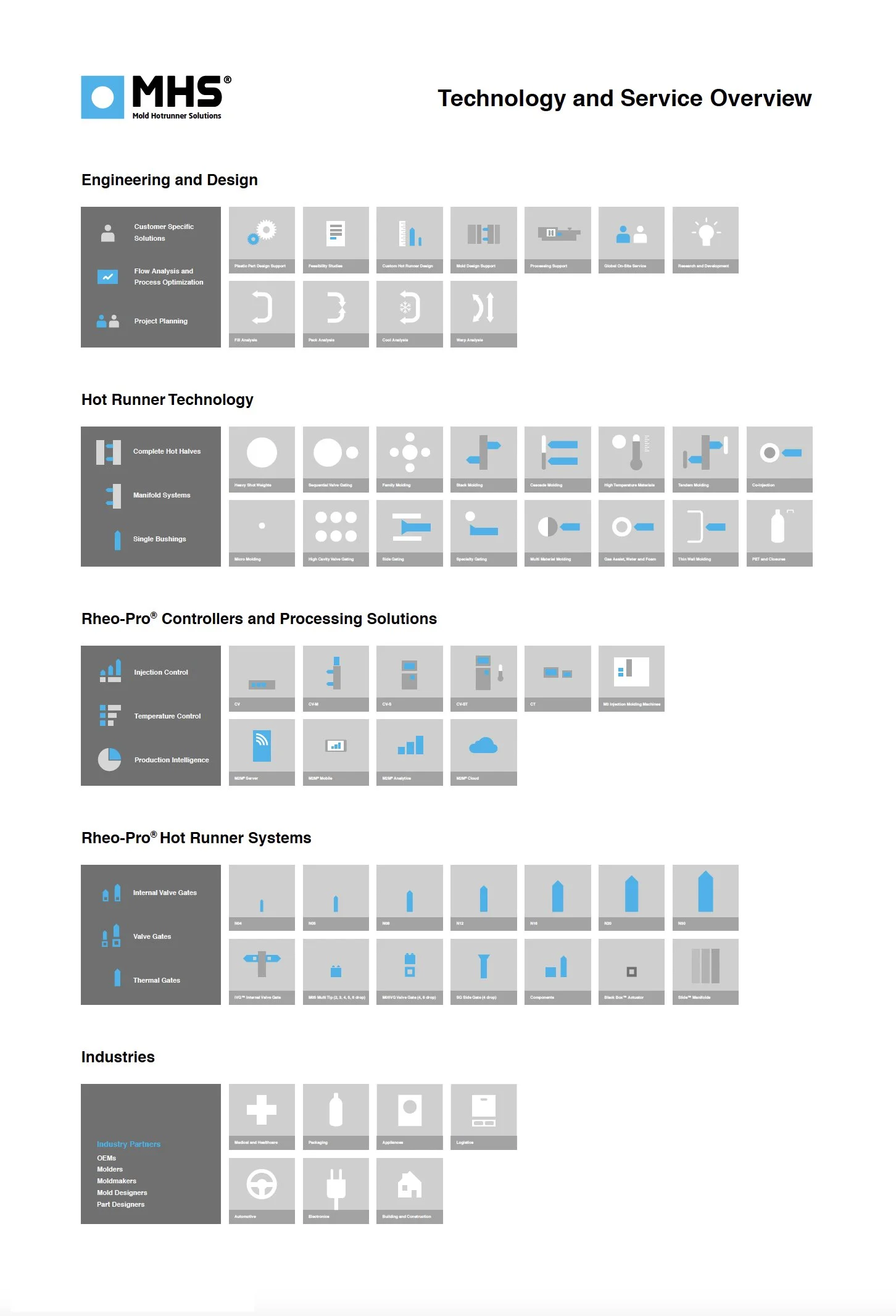

MHS hot runner systems offer the most versatile selection of gating methods, tip styles and nozzle sizes in the industry for a complete range of injection molding applications. MHS designs, builds and tests all of the components in the Rheo-Pro® hot runner catalog. These are the building blocks of every custom and pre-engineered hot runner system we manufacture. All our products are engineered for 24/7 production and a long molding life.

All in.

Our knowledgeable team of hot runner experts, designers and technical support staff draws from our extensive engineering and manufacturing resources to deliver the best performing, most innovative molding solutions available in the industry.

Rheo-Pro®

Hot Runners

MHS manufactures some of the world's most reliable, high performance hot runner systems. Our Rheo-Pro® hot runners are designed to deliver improved part quality, reduced mold maintenance and increased uptime for all injection molding applications. Systems are custom engineered for your specific application, and ship as turn-key hot halves, manifold systems, and single bushings.

Contact MHS for more information

The M3 micro molding machine by MHS is a high-precision, fully automated injection molding system designed for ultra-small, high-tolerance parts. Utilizing Isokor™ technology, it ensures consistent shot-to-shot quality with a cleanroom-ready, all-electric platform. The M3 excels in multi-cavity production with zero material waste, making it ideal for medical, electronics, and micro-optics applications. Its servo-driven, high-speed injection system delivers unmatched repeatability, while its modular design supports rapid mold changes, enhancing efficiency for demanding micro-molding projects.

M3 Micro Molding

Faster Injection

Fundamentally different from all two-stage micro molding machines on the market (screw and plunger-barrel combinations), the M3 takes advantage of melt compressibility and achieves ultra-high melt velocity by utilizing instant melt expansion, where the material remains constantly pre-pressurized (viscoelastic energy storage). The patented 3-step process creates a perfectly controlled injection cycle to produce the shortest possible fill time. The melt virtually explodes into the micro cavity with instantaneous fill.

Higher Output

The MDU (Melt Delivery Unit) is the heart of the M3 molding cell. It consists of a highly specialized valve gate hot runner system with integrated check valves, plungers, as well as an array of precise pressure, temperature and motion sensors. This controls all three main parameters of injection molding: pressure, temperature and time. It allows the operator to perfectly control the density and specific volume of the polymer melt. While the M3-D08 features 8 drops, models can range up to 32 drops.

Better Part Quality

The morphology of parts produced with uniform, high-pressurized melt is far superior to “slower” processes. The ratio between core material and frozen skin during cavity fill is directly effected by the speed at which the cavity fills. A micro cavity that fills faster produces more isotropic conditions, resulting in less temperate and pressure differences within the part while forming or solidifying. This produces perfectly uniform and stress-reduced parts (with low warpage and shrinkage) a critical characteristic for parts that are measured in microns.

Ready to start?

Take a minute to share your project details with us and we’ll explore the best options for your injection molded parts.