Controllers

Consistent part quality requires accurate control of your processing window. Our complete line of Rheo-Pro® hot runner controllers ensures you get the best performance with every shot.

Total control

Rheo-Pro® sequential valve gate controllers (or sequence controllers) provide accurate control of your injection process by opening and closing multiple gates for optimal fill of hot runner molded plastic parts. Both CV-S and CV-ST series controllers offer a robust graphic user interface for ease of operation and unlimited flexibility and are fully compatible with all MHS valve gate hot runner systems.

System Optimized

CV series controllers are ideal for regular molding machines without sequential fill capability. The PLC allows operators to program the controller to their specific molding needs. Each control zone can be programmed for time-based and/or volume-based injection. The nozzles for each control zone can be graphically shown on the touch screen display. The time from start of injection to end of packing (injection plus packing time) is entered into the Close Timer to switch all valves. Individual close times are also available. CV controllers do not require special options from the molding machine other than a simple start signal for the injection cycle. Each controller has an internal memory which stores numerous processing setups and programs with automatic mold identification capabilities.

Access anywhere

You want access to your production data - anywhere, anytime. MHS helps you stay in the lead by offering you complete control of your entire molding operation. M2M® manufacturing solutions enable real-time data logging and production reporting for multiple injection molding systems. Our Rheo-Pro® hot runner controllers and browser-based visualization tools offer a live, online overview of all your molds and injection molding machines, whether they are operating in a single plant or in multiple locations around the world.

If you can measure it, you can control it.

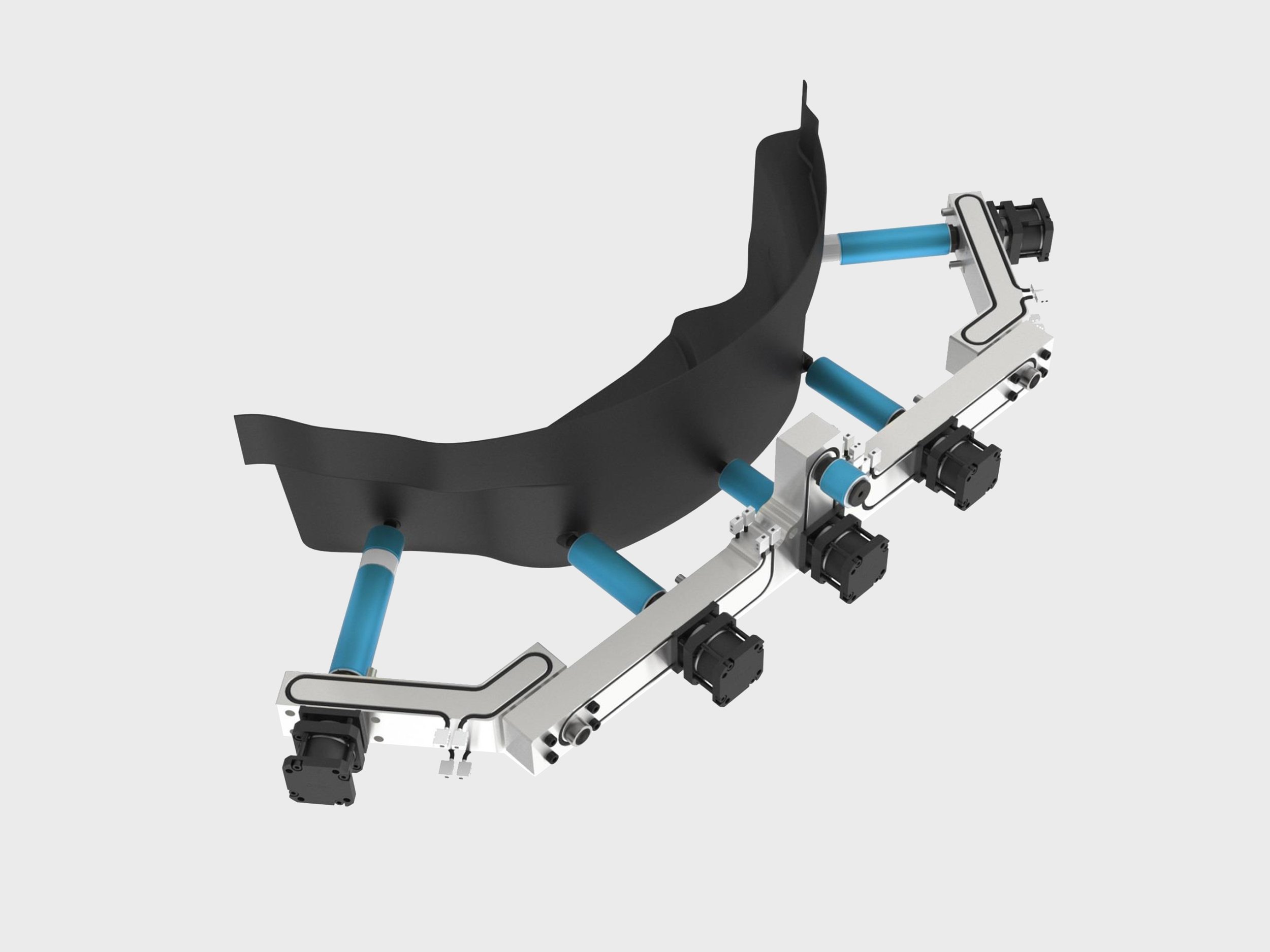

Loaded with state-of-the-art sensors, M3 series injection molding machines offer unparalleled performance in an extremely compact, user friendly package. All models of the M3 feature patented ISOKOR™ injection technology, specifically developed to address the unique challenges of molding small, direct gated plastic parts. From prototype to mass production, the revolutionary M3 family delivers superior part quality, speed, and flexibility.